Shandong Yanshanpump industry co., LTD will appear in Beijing cippe in March.

发布日期:2017-12-04 浏览次数:13993

Shandong YanShan pump co., LTD., five years of independent research and development of "intelligent and efficient servo rodless straight drive equipment" will appear in the 17th session of China international petroleum and petrochemical technology and equipment exhibition, welcome you come to visit. Pavilion: W2, booth no. : W2366.

Shandong yanshan pump industry co., LTD., as the leading enterprise of China's electric submersible pump system, began to produce the submersible electric pump in 1985, and the parameters of the products meet the performance requirements of American radar company and ODI company. February 2012 successfully developed servo direct drive submersible screw pump, the system has greatly improved, compared with foreign companies by the ground frequency vector control system, the underground cable, screw pump, protector, and motor, etc. Motor with a very low speed servo permanent magnet motor, remove the intermediate transmission reducer, solves the problem of low reliability, at the same time improve the efficiency of the system, product performance to reach the world advanced level. The servo direct drive oil screw pump has been used in daqing oilfield and shengli oilfield, receiving good oil recovery effect. Shandong YanShan servo submersible motor pump industry production, submersible screw pump system, which is dedicated to under complex conditions, such as fluid viscosity is not more than 8000 CPS, heavy oil emulsification well, high solid content, unstable flow, low production, such as the excessive hydraulic fracturing, servo direct drive submersible screw pump has better performance. In addition, the use of servo direct drive oil screw pump is easier to debug. Under certain conditions, the servo direct drive submersible screw pump can replace the pumping system perfectly. The servo submersible motor is different from the conventional electromagnetic induction motor, and the design of the servo submersible motor integrates the permanent magnet. The sintered rare earth permanent magnet requires little power to generate rotor flux. As a result, the power rating requirement phase at the same time, compared with the traditional induction motor, servo permanent magnet submersible motor, have a higher starting torque, is the traditional induction motor 2-3 times, improve system efficiency and reduce the power loss, lower system current and heat unit. Due to the low heat production, the cooling demand of servo submersible motor is lower than that of conventional motor, and can be operated at lower frequency. The servo submersible motor USES variable frequency vector control, so that the system can adjust the well condition change timely, optimize or eliminate the adverse effect of low velocity condition, thus ensuring maximum output. Therefore, the advantage of low yield heat, fast and superfine control makes the operation range of servo submersible motor increase. The permanent magnet motor USES the powerful rare earth magnet embedded inside, so that the motor can operate synchronously with the changing speed of the motor magnetic field. On the structure of servo submersible motor has higher power density than the induction motor, at the same time, the unit starts up, through the vector control of stator current and torque current, the servo system of submersible motor can output 2 ~ 3 times higher than the induction motor's starting torque, greatly improving the system of complex well type of reliable and economical operation. The servo direct drive oil screw pump avoids premature wear of sucker rod/tubing caused by the conventional sucker rod drive system due to the limitation of depth or deflecting well. And the traditional electric submersible screw pump system usually USES the traditional submersible motor to fit the oil screw pump system of the reducer, and its rotating speed is between 100-500. YanShan pump industry manufacturing servo direct drive submersible screw pump has similar configuration with submersible screw pump, the main difference is the system without the use of the reducer, the 10 servo permanent magnet motor, screw pump by inverter vector control servo submersible motor pump speed between 50-350 speed operation system without using reducer, improve the reliability of the system. In addition, compared with the conventional submersible motor, servo system of submersible motor has higher power efficiency compared with the traditional way of artificial lift, servo direct drive submersible screw pump is significantly improved the slope, the efficiency of heavy oil emulsification Wells and horizontal Wells. Compared with other schemes, the operation efficiency of the servo direct drive oil screw pump is significantly improved compared with other schemes for the slope part of the well and the horizontal section of the operation. The system has all the advantages of screw pump system, and there is no risk of wear of rod. It can be said that the system is the ideal form of servo direct drive oil screw pump, which will be better than the surface wear caused by environmental impact. As the system reduces the wear of sucker rod or pipe, the number of related workover and the cost are greatly reduced. The example proves that the service life of the servo direct drive submersible screw pump system is long, and the average can reduce 2~3 workover operations, which can save the customers thousands of manual intervention costs. Imagine a screw pump system with no lever and no speed reducer to understand the wonders of the servo direct drive submersible screw pump system. In a word, the servo - rod oil production expands the application range of the screw pump.

1. Range of main performance parameters.

(1) flow range: 1-147 m3 / day.

(2) lift: less than 2500 meters.

(3) maximum temperature: 120 degrees.

(4) the maximum viscosity allowable value: 8000 CPs. When crude oil is extracted, it can be heated and diluted, and the screw pump inlet is increased, which is more suitable for heavy oil recovery. , plus jijia1.

2. Applicable occasions.

Servo direct drive submersible screw pump has the common characteristics of submersible pump and screw pump, can be used in complex environment: heavy oil exploitation, heavy oil emulsification, deviated well and horizontal well, high Angle Wells in oil and gas drilling, mining crude oil with high viscosity, low flow Wells, mining crude oil with high abrasion resistance, high viscosity asphalt oil extraction.

Iii. Product features.

(1) no power drive rod: avoid the oil rod and tubing wear, save the large and heavy sucker rod, transfer the energy consumption, do not need the guide rod joint, reduce the cost and potential loss of the oil well;

(2) no downhole speed reducer: improved reliability, the servo submersible motor technology has no complex components, lower system cost, and reduce the maintenance/replacement cost of the reducer;

(3) no ground screw pump drive: eliminate the related safety hazards of ground drive; No ground rotating equipment to eliminate noise; Minimal environmental impact on ecologically sensitive sites;

(4) in submersible screw pump has a higher efficiency of the system: the motor adopts rare earth permanent magnet materials, no rotor copper loss, without the inefficient zone, servo submersible motors can save 15 to 30% of the power supply cost, high efficiency of screw pump technology perfect combination with efficient servo submersible motor;

(5) no chemical emulsification is required to reduce the use of chemicals or separation devices;

(6) adjustable speed of motor: 50-350 RPM, improve operation flexibility.

(7) vector control without encoder.

Control unit adopts no encoder unit vector control method, realized the speed, position and stator current of motor three closed loop control, precise control of motor speed and torque, flexible smooth drive motor, greatly reduce the loss of the system, with high power factor, large starting torque, high efficiency, etc.

(8) constant dynamic liquid level control.

Through the unit performance test, analysis and summary in detail, write the "constant dynamic liquid level control module, through the research, the characteristics of the screw pump technology working fluid level detection model is established, and the real-time monitoring of current, voltage, pressure, temperature and liquid level change, and according to the characteristic of oil viscosity large and small changes, intelligent submersible motor speed regulation, constant power operation, to prevent motor overload running. 24 hours for the user online monitoring ground wellhead temperature of crude oil, viscosity change model is set up, automatically adjust the number of thin oil, add thin oil minimize, maximize benefits, improve the stability of the production system.

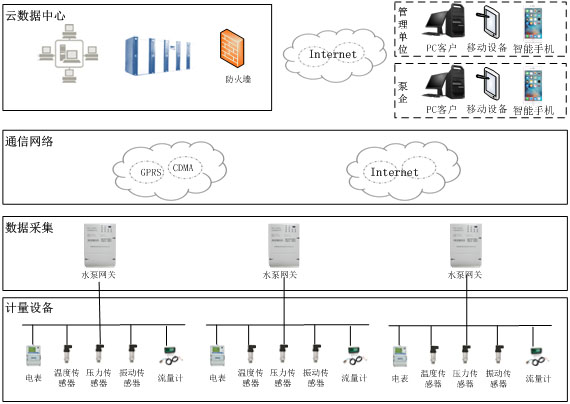

(9) remote data acquisition and control.

The ground controller with remote control and data acquisition ports, can through the mobile network to realize wireless remote data acquisition and control, to back the scene data and according to the site condition but end by PC background or cell phone APP for remote control of screw pump, stop, by adjusting the parameters of the system operation, etc. The sensor network security mechanism is introduced, and the information sent by the sensor node is encrypted, which is not easy to be cracked and utilized. With nodes authentication security mechanism, it is not easy to be counterfeit node, data analysis and alarm function is all ready, can according to the servo direct drive submersible screw pump database, automatically judge whether screw pump running in high efficient area, in a timely manner to provide users with warning information and trend analysis, and can print production date, month, quarter, annual reports, realize the oilfield digitalization management, save a lot of artificial cost.

Through the fields of application, you can see that direct drive servo rodless equipment compared with a thick pump, improve the system efficiency is 50-60%, solve the low efficiency, the system is not suitable for viscous well and deviated well, and covers an area of small, low noise; Compared with the commonly used submersible screw pump, the intermediate transmission reducer is removed, which solves the problem of low reliability and improves the system efficiency by 25-30%. Thus, both technical performance, service life and cost performance, compared with existing products at home and abroad, shandong YanShan servo direct drive submersible screw pump pump industry development, there is a very large competitiveness, is a ideal oil field production equipment upgrading products.